Global Executive Summary Additive Manufacturing Market: Size, Share, and Forecast

CAGR Value

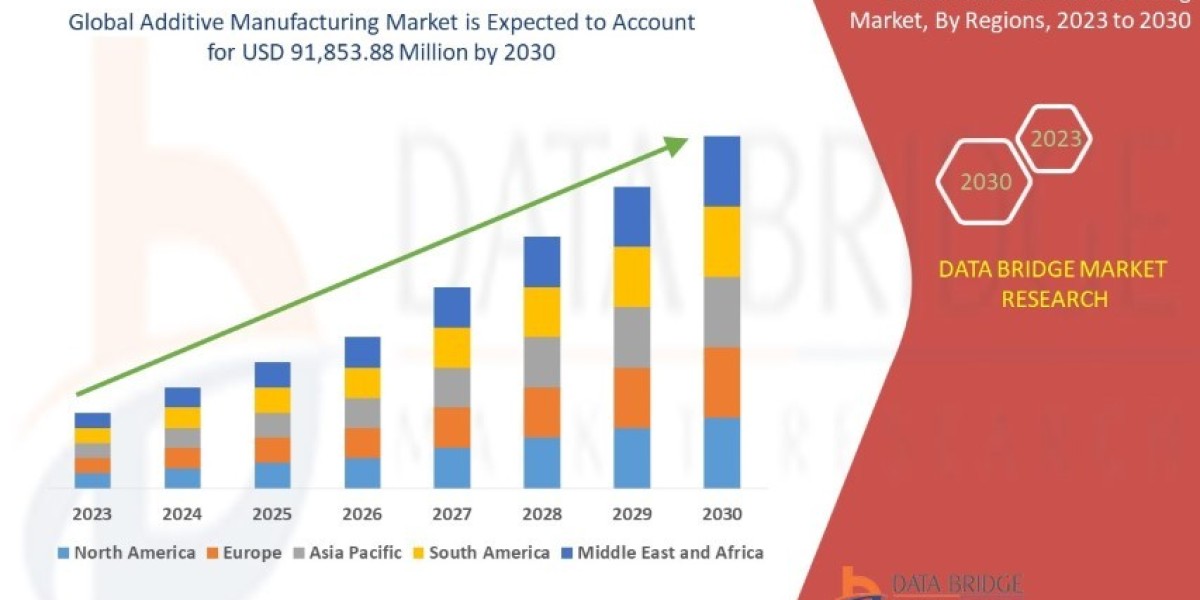

The additive manufacturing market size was valued at USD 91.84 billion in 2024 and is projected to reach USD 419.22 billion by 2032, with a CAGR of 20.90% during the forecast period of 2025 to 2032.

To gain meaningful market insights and thrive in this competitive market place, Additive Manufacturing Market survey report plays a key role. The report takes into account the market type, organization size, accessibility on-premises and the end-users’ organization type, and accessibility at global level in areas such as North America, South America, Europe, Asia-Pacific, Middle East and Africa. Additive Manufacturing Market report displays several parameters related to Additive Manufacturing Market industry which are systematically studied by the experts. These parameters mainly include latest trends, market segmentation, new market opening, industry forecasting, target market analysis, future directions, opportunity identification, strategic analysis, insights and innovation.

The universal Additive Manufacturing Market report helps make known uncertainties that may crop up due to changes in business activities or introduction of a new product in the market. This market research report provides thorough information about a target markets or customers. Moreover, it takes into account both qualitative and quantitative techniques of market analysis. Focus groups and in-depth interviews are included for qualitative analysis whereas customer survey and analysis of secondary data has been carried out under quantitative analysis. It helps companies to take decisive actions to deal with threats in the niche market. An excellent Additive Manufacturing Market report proves to be a sure option to help grow the business.

Stay ahead with crucial trends and expert analysis in the latest Additive Manufacturing Market report.Download now:

https://www.databridgemarketresearch.com/reports/global-additive-manufacturing-market

Additive Manufacturing Industry Overview

**Segments**

- By Offering: Hardware, Software, Services

- By Process: Material Jetting, Binder Jetting, Material Extrusion, Material Bed Fusion, Directed Energy Deposition, Sheet Lamination

- By Material: Metal, Polymer, Ceramic, Others

- By Application: Prototyping, Tooling, Functional Part Manufacturing

- By End-Use Industry: Aerospace & Defense, Automotive, Healthcare, Industrial, Others

Additive manufacturing, also known as 3D printing, has witnessed substantial growth in recent years due to advancements in technology and increasing demand for customized products. The global additive manufacturing market is segmented based on offering, process, material, application, and end-use industry. In terms of offering, the market is categorized into hardware, software, and services, with hardware being the dominant segment due to the high demand for printers and materials. The process segment includes material jetting, binder jetting, material extrusion, material bed fusion, directed energy deposition, and sheet lamination, each offering unique advantages for different applications. Material segmentation consists of metal, polymer, ceramic, and other materials, with metal being the most widely used due to its strength and durability. The application segment includes prototyping, tooling, and functional part manufacturing, with prototyping being a key driver of the market as it allows for rapid product development. Lastly, the end-use industry segment covers aerospace & defense, automotive, healthcare, industrial, and other sectors, each utilizing additive manufacturing for various purposes.

**Market Players**

- Stratasys Ltd.

- 3D Systems, Inc.

- EOS GmbH

- General Electric

- Materialise NV

- Siemens AG

- Renishaw PLC

- HP Development Company, L.P.

- ExOne

- Voxeljet AG

Several key players dominate the global additive manufacturing market, including Stratasys Ltd., 3D Systems, Inc., EOS GmbH, General Electric, Materialise NV, Siemens AG, Renishaw PLC, HP Development Company, L.P., ExOne, and Voxeljet AG. These companies are investing heavily in research and development to introduce innovative solutions and expand their product portfolios. Stratasys and 3D Systems, as pioneers in the 3D printing industry, continue to lead the market with their cutting-edge technologies. On the other hand, industrial giants like General Electric and Siemens have integrated additive manufacturing into their operations to streamline production processes. Materialise NV and Renishaw PLC specialize in software and services for additive manufacturing, catering to a wide range of industries. HP Development Company, L.P. has made significant strides in the 3D printing market with its Multi Jet Fusion technology. Overall, these market players play a crucial role in shaping the future of additive manufacturing across various industries.

Additive manufacturing, or 3D printing, continues to revolutionize the manufacturing industry with its ability to create complex geometries and customizable products. One of the key trends shaping the market is the adoption of additive manufacturing for end-use production, moving beyond just prototyping and tooling applications. Industries such as aerospace and defense, automotive, and healthcare are increasingly leveraging 3D printing technology to manufacture functional parts due to its cost-effectiveness and design flexibility. This shift towards end-use production is driving the demand for high-performance materials and advanced processes that can meet the stringent requirements of these industries.

In terms of materials, the market is witnessing a rise in the development of new metal alloys and advanced polymers specifically designed for additive manufacturing. Metal 3D printing, in particular, is gaining traction in industries like aerospace and healthcare where parts need to withstand high temperatures and mechanical stresses. Furthermore, the integration of ceramics and composites in additive manufacturing is opening up new possibilities for applications requiring high strength-to-weight ratios and thermal resistance.

Another emerging trend in the additive manufacturing market is the focus on sustainability and environmental impact. Companies are increasingly exploring bio-based and recycled materials to reduce waste and mitigate the carbon footprint of additive manufacturing processes. Additionally, advancements in post-processing techniques are enabling the recycling and reusing of 3D printed parts, contributing to a more sustainable approach to manufacturing.

The market is also witnessing a shift towards hybrid manufacturing systems that combine traditional subtractive manufacturing methods with additive manufacturing technologies. These hybrid systems offer the advantages of both processes, allowing for intricate designs produced with additive manufacturing to be finished with high precision and surface quality using subtractive methods. This integration of technologies is expanding the capabilities of additive manufacturing and broadening its application across industries.

In conclusion, the additive manufacturing market is dynamic and continuously evolving, driven by technological innovations, changing end-user requirements, and a growing emphasis on sustainability. As key players continue to invest in research and development to enhance their product offerings and expand their market presence, the future of additive manufacturing looks promising. With applications ranging from aerospace to healthcare and materials evolving to meet industry demands, additive manufacturing is poised to play a significant role in the manufacturing landscape of the future.The global additive manufacturing market is experiencing significant growth and transformation driven by technological advancements, changing end-user requirements, and a focus on sustainability. One of the key trends shaping the market is the increasing adoption of additive manufacturing for end-use production across industries such as aerospace, automotive, and healthcare. Manufacturers are moving beyond prototyping and tooling applications to leverage 3D printing technology for producing functional parts due to its cost-effectiveness and design flexibility. This shift is fueling the demand for high-performance materials and advanced processes that can meet the stringent requirements of these industries.

In terms of materials, there is a growing emphasis on the development of new metal alloys, advanced polymers, ceramics, and composites tailored for additive manufacturing applications. Metal 3D printing is gaining traction in sectors like aerospace and healthcare where components must exhibit high strength, withstand extreme conditions, and meet strict regulatory standards. The integration of ceramics and composites in additive manufacturing is also creating opportunities for applications that demand superior strength-to-weight ratios and thermal resistance.

Another emerging trend in the additive manufacturing market is the focus on sustainability and environmental impact. Companies are exploring bio-based and recycled materials to reduce waste and minimize the carbon footprint of 3D printing processes. Advancements in post-processing techniques are enabling the recycling and reusing of 3D printed parts, contributing to a more sustainable approach to manufacturing.

Hybrid manufacturing systems, which combine additive manufacturing with traditional subtractive methods, are gaining traction in the market. These systems offer the benefits of both processes, allowing for intricate designs produced with additive manufacturing to be finished with high precision and surface quality using subtractive methods. The integration of these technologies is expanding the capabilities of additive manufacturing and broadening its applications across various industries.

In conclusion, the additive manufacturing market is dynamic and evolving rapidly, with continuous advancements in technology and material development driving its growth. Key players in the market are investing in research and development to enhance their product offerings and expand their market presence. With a wide range of applications across industries, from aerospace to healthcare, and a focus on sustainability and innovation, additive manufacturing is poised to play a crucial role in the future of manufacturing, revolutionizing production processes and product development worldwide.

Access detailed insights into the company’s market position

https://www.databridgemarketresearch.com/reports/global-additive-manufacturing-market/companies

Alternative Research Questions for Global Additive Manufacturing Market Analysis

- What is the current market valuation of the Additive Manufacturing Market?

- At what CAGR is the Additive Manufacturing Market projected to grow?

- Which are the top-performing product categories in this market?

- Who are the emerging players in the Additive Manufacturing Market?

- What regions are witnessing rapid demand in the Additive Manufacturing Market?

- Which countries show significant market potential?

- What are the major driving factors behind this Additive Manufacturing Market growth?

- How has the Additive Manufacturing Market changed over the past five years?

- What are the opportunities for new entrants?

- What is the competitive landscape of the market?

- What technological advancements are influencing the Additive Manufacturing Market?

- Which segment holds the largest market share?

- What partnerships or collaborations are influencing the Additive Manufacturing Market?

- What is the role of e-commerce in driving sales?

Browse More Reports:

Global Semi-Autonomous Delivery Robots Market

Global Pro AV (Audio-Visual) Market

Global Smart Distribution for Commercial Application Market

North America Corrugated Board Packaging Market

North America Wearable Devices Market

Global Automotive Transmission Engineering Services Outsourcing Market

Middle East and Africa Industrial Metrology Market

Global Decorations and Inclusions Market

India Business Process Outsourcing (BPO) Market

Global Recreational Vehicle (RV) Awnings Market

North America Hospital Laboratory Information Management Systems Market

Global Bus Flooring Market

Global Colony Stimulating Factors Market

Global Biohazard Bags Market

Global Video Door Phones Market

Asia-Pacific High Strength Steel Market

Global Airborne Telemetry Market

Global Dermatitis Market

Global Heat Pumps Market

Global Farm Healthcare Market

Global Bamboo Furniture Market

Global Contraceptives Market

Global Pilates Equipment Market

North America Hummus Market

Global Probiotics Market

About Data Bridge Market Research:

An absolute way to forecast what the future holds is to comprehend the trend today!

Data Bridge Market Research set forth itself as an unconventional and neoteric market research and consulting firm with an unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process. Data Bridge is an aftermath of sheer wisdom and experience which was formulated and framed in the year 2015 in Pune.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email:- corporatesales@databridgemarketresearch.com