Step-by-Step Ordering Your First Custom Boxes

Securing custom boxes for your brand is one of the most strategic moves for effective packaging, customer appeal, and product protection. The process may seem challenging at first, but with the right guidance, you can confidently navigate the various phases and achieve packaging that matches your business goals. This in-depth guide walks you through the steps required to order your first custom boxes, from defining your needs to approving the final design and arranging delivery.

Zee Custom Boxes UK: Your Packaging Partner

When searching for reliable packaging providers, Zee Custom Boxes UK is a trusted choice for businesses seeking effective and distinctive packaging solutions. With a wide range of box styles, sturdy materials, and professional support, they make it easier for you to move through each stage of your order.

Understanding Custom Boxes and Their Benefits

Custom boxes offer more than just enclosure for your products. They communicate your brand values, make a powerful first impression, and cater to the logistics of your supply chain.

What Are Custom Boxes?

Custom boxes are packaging produced based on your specific size, printing, and material requirements. These are not off-the-shelf solutions; instead, they are produced after understanding the product dimensions, weight, market, and intended customer experience.

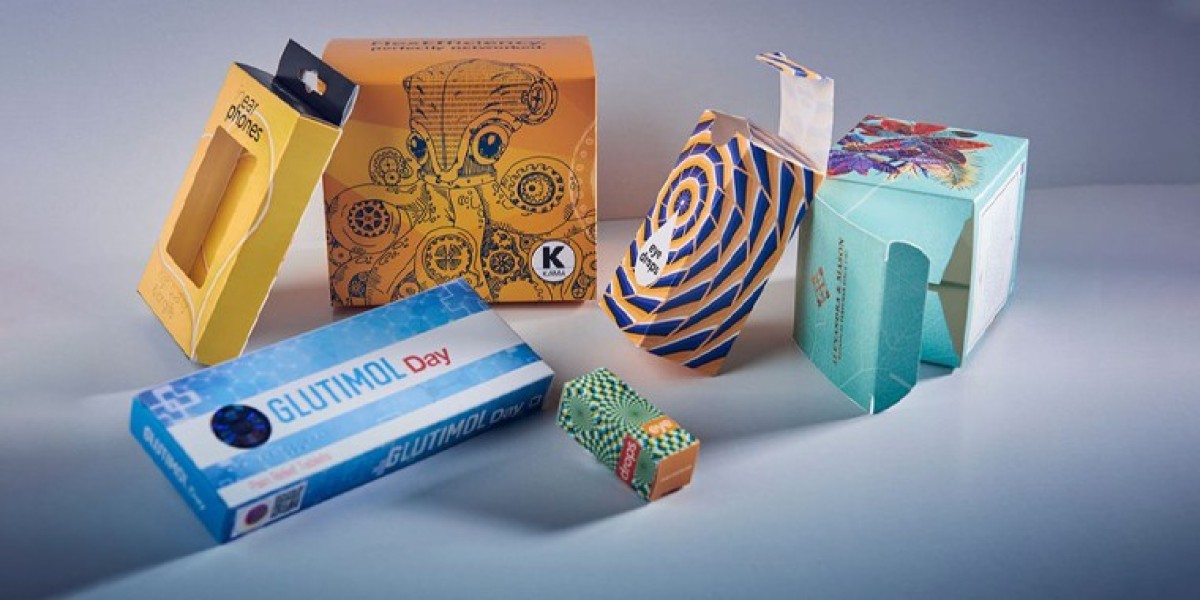

Custom packaging solutions include:

Rigid boxes for gifts and luxury products

Corrugated boxes for shipping and e-commerce

Folding cartons for retail shelves

Specialty boxes with unique inserts

Each type brings unique advantages depending on the placement and industry.

Why Choose Custom Packaging?

Companies invest in custom packaging to:

Stand out in competitive markets

Protect delicate or high-value items

Establish an unmistakable brand image

Share important details like instructions or promotions

Effective packaging supports marketing strategies and operational efficiency by reducing returns, claims, or damage.

Initial Planning Before Ordering

A smooth order process begins with understanding your product needs, quantities, and brand objectives.

Define Your Packaging Requirements

Before you contact a manufacturer, gather all the essential details about your products:

What are the product’s dimensions, weight, and shape?

Will the item require extra cushioning?

Is it fragile or temperature sensitive?

How will your product travel to the customer—store shelves, shipping, or direct delivery?

Create a simple table to organize your packaging requirements.

| Product Name | Dimensions (cm) | Weight (kg) | Fragile (Yes/No) | Delivery Method |

|---|---|---|---|---|

| Example Shirt | 30x20x3 | 0.3 | No | Ship to warehouse |

| Chocolate Box | 15x12x5 | 0.7 | Yes | Direct to customers |

Consider Branding and Design Elements

Identify your company logo, color palette, preferred graphics, and key messaging. Think about any QR codes, barcodes, or regulatory symbols that should appear.

| Box Element | Needed (Yes/No) | Notes |

|---|---|---|

| Logo | Yes | Front and side panels |

| Brand Colors | Yes | Main accent throughout |

| Special Printing | Yes | Embossed finish for logo |

Having these details ready accelerates the ordering process and ensures no key branding gets missed.

Requesting a Quote and Exploring Materials

Before placing an order, gather pricing and material samples. This phase helps balance your budget with quality expectations.

Contact the Packaging Provider

Reach out to the packaging supplier and provide your prepared information. Most companies, including Zee Custom Boxes UK, have online contact forms or request portals for custom quotes. Share quantities, dimensions, materials of interest, and design files or ideas.

Compare Material and Printing Options

Custom boxes are available in various materials, each affecting cost, appearance, and durability.

| Material Type | Properties | Cost | Ideal Use |

|---|---|---|---|

| Corrugated Card | Lightweight, robust, recyclable | Lower | Shipping, e-commerce, bulk orders |

| Rigid Board | Dense, premium feel, sturdy | Higher | Gifts, electronics, luxury products |

| Kraft Paper | Natural, eco-friendly appearance | Moderate | Organic, sustainable brands |

Ask for samples or images to ensure the material matches your requirements.

Request Price Estimation

Suppliers will prepare a price proposal based on your order size, specifications, and printing needs. This may include costs for:

Design setup (one-time for first order)

Per-unit price (varies with quantity)

Shipping or delivery charges

Review quotes and clarify any concerns before moving forward.

Finalizing Design and Order Details

Now comes the most creative phase—finalizing the design and confirming all order details with your supplier.

Approve the Design Mockup

The supplier’s design team will produce a digital or physical mockup of your box. Examine the following:

Placement of artwork and logos

Correct spelling and graphics clarity

Accurate color reproduction

Proper sizing and fit for your product

Ask for revisions if anything doesn’t align with your vision.

Confirm Order Specifications

Before production, it’s essential to review all specifications with the supplier:

Box style, material, and finishing

Print colors (Pantone or CMYK references)

Quantity and delivery schedule

Shipping or packaging needs (flat-packed or pre-assembled)

Securing written confirmation of these points helps avoid any misunderstandings later.

Production, Quality Checks, and Delivery

With the design approved and order confirmed, suppliers now begin manufacturing. This segment involves several steps that ensure your boxes arrive as expected.

Monitoring Production Progress

Keep in touch with your supplier during production. Reputable companies will update you on progress, expected completion dates, and any issues.

Quality Control and Sample Approval

Some providers offer a pre-shipment sample for approval. Use this to verify print quality, box strength, and any finishing touches.

| Checklist Item | Approved (Yes/No) | Comments |

|---|---|---|

| Material Thickness | Yes | Meets requirements |

| Color and Graphics | No | Logo too light |

| Structural Strength | Yes | Box fully supports item |

Notify your supplier of any necessary corrections before the full order leaves the facility.

Shipping and Receiving Your Custom Boxes

Once manufacturing and quality checks are completed, the order is packaged and shipped. Clarify delivery details in advance:

Delivery address and point of contact

Receiving schedule and logistics instructions

Inspection upon delivery for quantity and quality

Unpack a sample upon arrival to confirm standards are met.

Ongoing Collaboration and Next Steps

Choosing custom packaging is often the start of a long-term relationship with your supplier. Use feedback from this process to improve future orders.

Collect Feedback

Once boxes reach your warehouse or end customers, gather feedback regarding:

Fit and protection on arrival

Customer impressions of the box

Cost and efficiency in logistics

This information will guide adjustments for your next order.

Plan for Future Orders

If certain box sizes or designs prove consistently valuable, discuss stocking or volume discounts with your supplier. Share plans for new product launches in advance to ensure availability of suitable packaging.