3D printing has revolutionized the way we create objects, but it is not without its challenges. Understanding 3D printing troubleshooting: 15 most common problems & solutions can significantly improve your printing experience. Below, we delve into the most frequent issues encountered in 3D printing and provide practical solutions.

1. Poor Adhesion to the Build Plate

One of the most common problems is poor adhesion of the print to the build plate. This can lead to warping or the print detaching mid-process. To enhance adhesion, ensure that the build plate is clean and properly leveled. Additionally, consider using adhesives like glue sticks or specialized sprays.

2. Warping

Warping occurs when the edges of a print lift off the build plate. This issue is often caused by rapid cooling. To mitigate warping, you can:

- Use a heated bed.

- Print with a brim or raft.

- Adjust the ambient temperature.

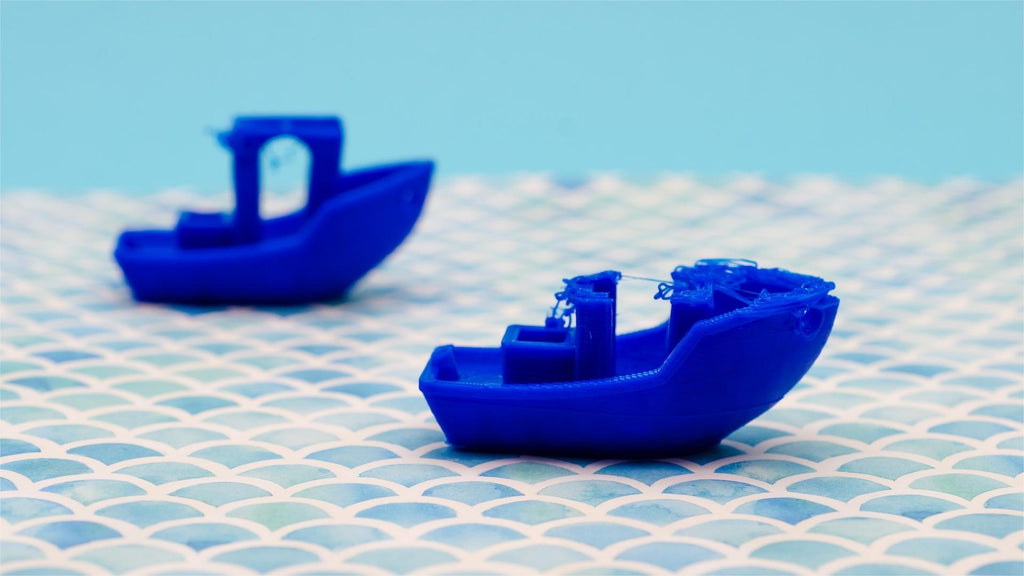

3. Stringing

Stringing refers to the unwanted strands of plastic that appear between parts of a print. This can be minimized by adjusting the retraction settings in your slicer. If you notice excessive stringing, consider increasing the retraction distance or speed.

4. Layer Separation

Layer separation can occur when layers do not bond properly. This issue is often due to insufficient temperature settings. Ensure that your nozzle temperature is appropriate for the filament being used. If necessary, increase the temperature slightly to improve layer adhesion.

5. Under-extrusion

Under-extrusion results in gaps in the print due to insufficient filament being extruded. This can be caused by a clogged nozzle or incorrect flow rate settings. Regularly clean your nozzle and check your slicer settings to ensure optimal flow rates.

6. Over-extrusion

Conversely, over-extrusion leads to excess filament being laid down, resulting in blobs and uneven surfaces. To address this, reduce the flow rate in your slicer settings or calibrate your extruder steps per millimeter.

7. Nozzle Clogs

Nozzle clogs can halt your printing process entirely. Regular maintenance is essential. If you encounter a clog, consider performing a cold pull or using a cleaning filament to clear the nozzle.

8. Print Inconsistencies

Inconsistencies in prints can arise from various factors, including filament quality and printer calibration. Always use high-quality filament and ensure your printer is calibrated correctly to maintain print quality.

9. Filament Issues

Filament can absorb moisture from the air, leading to poor print quality. Store your filament in a dry environment and consider using a filament dryer if necessary.

10. Electrical Issues

Electrical problems can lead to unexpected shutdowns or failures during printing. Ensure that all connections are secure and consider using a UPS (Uninterruptible Power Supply) to protect against power surges.

11. Software Errors

Software glitches can cause printing errors. Always ensure that your slicing software is up to date and compatible with your printer. If issues persist, consider reinstalling the software.

12. Mechanical Failures

Mechanical failures, such as loose belts or misaligned axes, can lead to print inaccuracies. Regularly inspect and maintain your printer's mechanical components to prevent these issues.

13. Temperature Fluctuations

Temperature fluctuations can affect print quality. Ensure that your printer is in a stable environment, away from drafts or direct sunlight.

14. Incorrect Print Settings

Using incorrect print settings can lead to a variety of issues. Always double-check your slicer settings before starting a print to ensure they match the filament and printer specifications.

15. Lack of Experience

Finally, lack of experience can lead to many common problems. Engaging with the 3D printing community and utilizing resources like the 3D printing troubleshooting guide can provide valuable insights and solutions.

By understanding these 3D printing troubleshooting: 15 most common problems & solutions, you can enhance your printing experience and achieve better results. Remember, every problem has a solution, and with patience and practice, you can become a proficient 3D printer.