In modern electrical and electronic applications, an EI Transformer Factory represents the foundation of innovation, reliability, and consistent power conversion. These factories are where precision engineering meets energy efficiency, producing vital components that serve industries such as telecommunications, automation, and consumer electronics. Each transformer manufactured within such a facility plays a crucial role in voltage regulation, isolation, and the safe transfer of electrical energy between circuits.

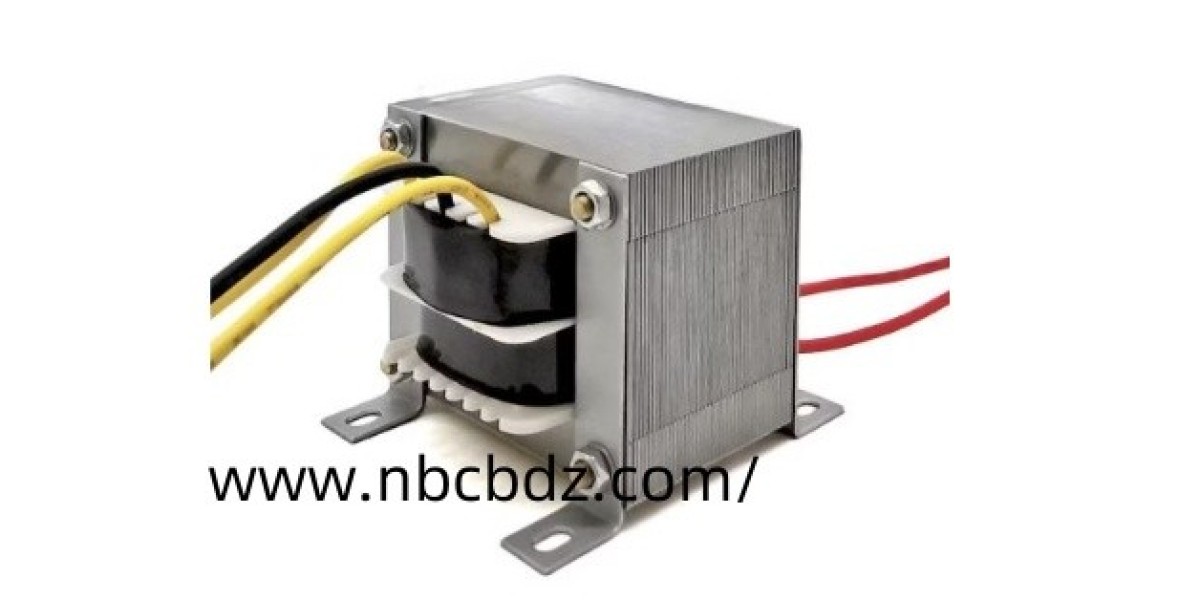

Transformers with EI cores derive their name from the E-shaped and I-shaped laminated silicon steel sheets used in their design. This traditional yet highly efficient construction minimizes eddy current losses, providing a cost-effective and durable solution for various power applications. Within a factory setting, the focus extends beyond production—it involves research, material selection, testing, and continuous refinement to ensure optimal performance under different electrical conditions.

The Role of EI Transformers in Modern Technology

EI transformers are essential in many low-frequency applications, especially where compact size and reliability are critical. They are commonly used in audio amplifiers, chargers, lighting systems, control panels, and household appliances. The design allows excellent magnetic performance while keeping manufacturing economical. Additionally, their structure helps to reduce electromagnetic interference, making them ideal for sensitive electronic devices that demand steady and noise-free power.

A specialized factory like ChuangBiao emphasizes precision in every production step. From selecting core materials to coil winding, insulation application, and vacuum impregnation, each detail ensures that the final transformer meets strict performance standards. Automated production lines enhance consistency, while quality control systems test for insulation strength, load capacity, and efficiency before the units are released for use.

Innovation and Sustainability in Transformer Production

Today's energy landscape demands not only performance but also sustainability. Manufacturers such as ChuangBiao continuously adopt eco-friendly production methods, such as using recyclable materials and implementing low-waste insulation techniques. Advanced machinery helps reduce material waste, while improved cooling and lamination processes extend transformer life, reducing maintenance and replacement needs over time.

The push toward automation in production also contributes to accuracy and repeatability. By integrating intelligent testing systems and digital process control, the factory ensures that each transformer adheres to both domestic and international standards. This combination of tradition and modern innovation helps balance quality with efficiency.

Ensuring Safety and Reliability

Safety remains a top priority in transformer design and assembly. EI transformers must operate within precise temperature and voltage limits to ensure reliable performance. Therefore, factories invest heavily in thermal management systems, protective coatings, and reinforced insulation layers. These design features not only improve safety but also enhance longevity under continuous load.

Customization and Market Adaptability

A major strength of a dedicated transformer facility lies in its ability to offer customized solutions. Whether for industrial machinery, renewable energy systems, or consumer electronics, clients can request specific voltage ratings, coil designs, or mounting styles. Factories like ChuangBiao provide engineering consultation to optimize the design for intended applications, ensuring that each transformer fits seamlessly into the customer's system.

As industries continue to evolve with new energy systems and automation technologies, EI transformer factories stand at the intersection of reliability and innovation. Their role is not only to meet existing power demands but also to anticipate future challenges by developing more efficient, sustainable, and adaptable solutions for diverse sectors.

Learn more about precision-engineered EI transformers and advanced electrical components at https://www.nbcbdz.com/product/