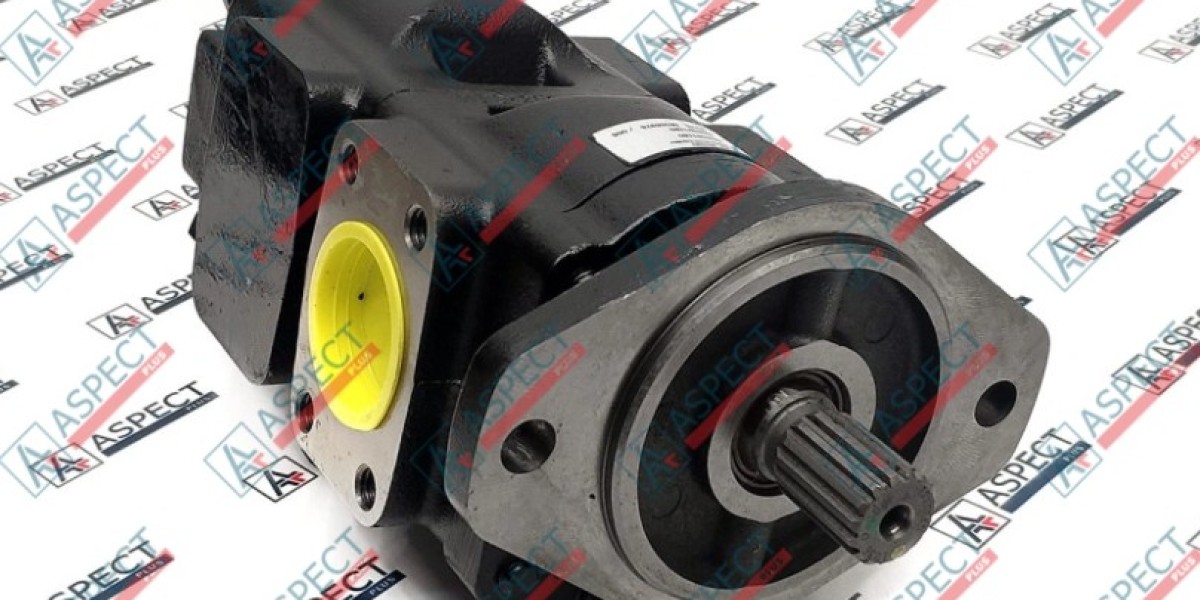

Parker hydraulic pumps are widely utilized in heavy equipment and industrial systems due to their robust design and high-pressure capabilities. They are engineered to deliver consistent, stable pressure essential for the precise and efficient operation of cylinders and hydraulic motors. However, one of the most frustrating and potentially damaging symptoms of hydraulic malfunction is unstable pressure. This fluctuating pressure directly leads to jerky operation, loss of lifting capacity, and premature wear and tear across the entire hydraulic system. This article provides an expert analysis of the primary causes of unstable pressure in Parker hydraulic pumps, details systematic diagnostics methods, and emphasizes the critical role of valve repair in restoring system integrity and reliability.

The Critical Role of Pressure Stability

Pressure is the force that defines the performance of a hydraulic system. In Parker pumps, the pressure is regulated by internal components and external valves (relief valves, compensators). Unstable pressure—whether it manifests as pulsing, surging, or erratic drops—indicates that the balance between fluid flow, resistance, and relief is fundamentally broken. This instability often points to a failure in the valve mechanism or a critical compromise in fluid integrity.

Primary Causes of Unstable Pressure in Parker Pumps

While wear in the rotating group (pistons and cylinder barrel) can cause low overall pressure, instability is typically rooted in fluid dynamics and control components.

1. Aeration and Cavitation (Fluid Integrity)

- Aeration: Air entering the hydraulic fluid through a leaky suction line or a faulty pump shaft seal is a major cause of instability. Air bubbles compress under pressure, leading to spongy operation, foaming, and pressure surges as the air rapidly expands and contracts.

- Cavitation: This occurs when the pump inlet is restricted (e.g., a clogged suction filter). The pump "starves" for fluid, creating vapor bubbles that violently implode in the high-pressure zone. This implosion causes noise and vibration, rapidly damages the pump's internal surface, and leads to pressure pulsation.

2. Valve Malfunctions (Control Component Failure)

The most common source of unstable pressure is a fault in the control valves that meter the system's output:

- Sticking Relief Valve: The main relief valve is designed to open at a set pressure to protect the system. If it is sticking or fluttering due to contamination or damaged springs, it will open and close erratically, causing the system pressure to constantly surge and drop.

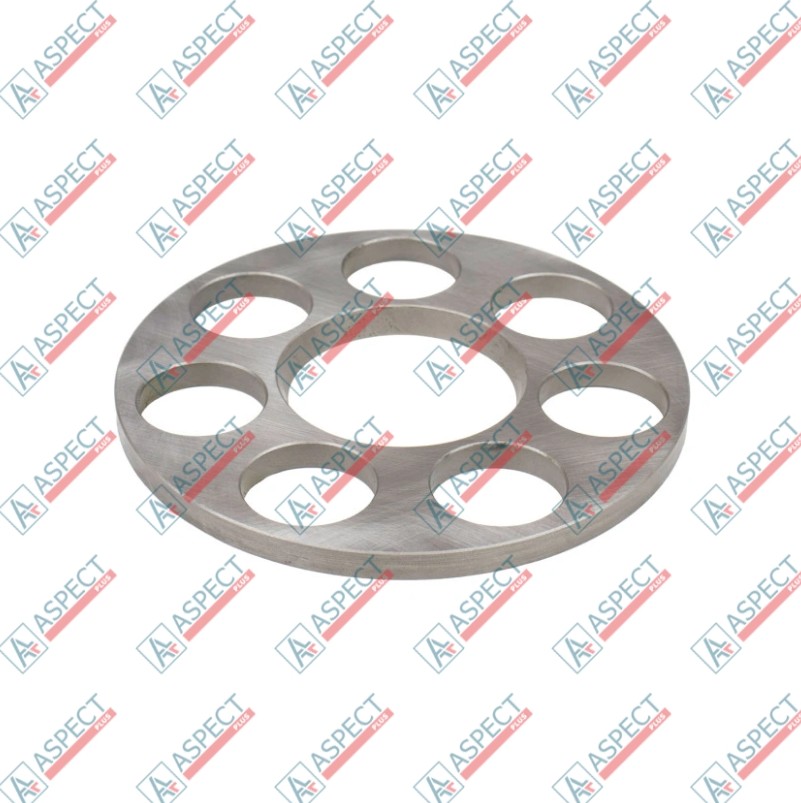

- Worn Compensator or Regulator: Parker variable displacement pumps use a compensator valve to adjust the pump's swashplate angle to maintain constant pressure regardless of flow demands. Wear or scoring on the compensator spool allows internal leakage or sluggish movement, resulting in a failure to maintain stable pressure under load.

- Damaged Seals or O-rings: Failure of internal seals or O-rings on the pump's compensator or control manifold allows high-pressure fluid to escape intermittently, leading to unpredictable drops in pressure.

3. Contamination and Filtration Issues

- Particulate Contamination: Abrasive debris circulating in the hydraulic system causes scoring on the tight-tolerance surfaces of control valves and compensator spools. This scoring increases internal leakage and compromises the smooth movement of the valve, directly causing pressure instability.

- Clogged Filters: A severely clogged return or pressure filter increases backpressure in the system, leading to erratic operation of the relief valve and overall instability.

Diagnostics: Pinpointing the Cause of Pressure Fluctuation

Accurate diagnostics requires a systematic approach, starting with the simplest checks.

- Visual and Noise Inspection: Listen for noise and vibration (whining or banging suggests cavitation/aeration). Visually check the hydraulic fluid in the tank for foaming (aeration) and check the suction line for leaks (air ingress).

- Pressure Gauge Monitoring: Connect a precision pressure gauge to the main system output. Monitor the gauge needle while the heavy equipment is under light and heavy load. Excessive, rapid fluctuation confirms pressure instability.

- Filter Check: Inspect the suction filter and pressure filters for clogging or damage. Replace them if necessary.

- Oil Analysis: Laboratory analysis of the hydraulic fluid is critical for confirming contamination (water, air, particulates) and detecting early signs of internal pump or valve wear through wear metal analysis.

- Valve Isolation and Testing: If the pump is suspected, the relief valve should be isolated and bench-tested to confirm its opening pressure and reseating characteristics. If the pump still exhibits instability after valve repair or replacement, the pistons or swashplate mechanism may be internally damaged.

Repair and Prevention: The Role of Quality Valve Repair

Once the unstable pressure is traced to the control mechanism, valve repair is the targeted solution.

- Precision Valve Repair: Repairing Parker valves involves meticulous cleaning, replacing damaged springs, and, most importantly, replacing the seals and O-rings. If the spool or bore is scored due to contamination, the valve may need replacement, as precision machining is required to restore the necessary tight tolerances.

- Genuine Parts Mandate: When conducting any valve repair, using genuine Parker parts for seals, springs, and spools is essential. Low-quality spare parts will quickly fail under the high pressures of a Parker hydraulic pump, causing the instability to immediately return.

- Flushing and Prevention: After repair, the entire hydraulic system must be flushed and refilled with clean fluid. Installing new, high-efficiency filters is a mandatory preventive maintenance step to protect the newly repaired valve and pump from further contamination.

Our company Aspect Plus offers genuine Parker hydraulic pumps and valve components, as well as expert consultation on diagnostics and repair, ensuring the reliability and longevity of your hydraulic system.

Conclusion

Unstable pressure in Parker hydraulic pumps is a serious operational fault that primarily signals a breakdown in fluid integrity (aeration/cavitation) or a malfunction in the control valves. Addressing this issue requires accurate diagnostics to pinpoint the root cause and a commitment to professional valve repair using quality spare parts. By prioritizing preventive maintenance and insisting on genuine Parker parts, you eliminate the destructive forces of contamination and restore the consistent, stable pressure essential for the efficient operation and reliability of your heavy equipment.

For expert diagnostics, genuine Parker valves, and reliable hydraulic pump repair solutions, contact the specialists at Aspect Plus.