In the world of advanced glazing, SGP interlayer films represent a high-performance ionic interlayer inserted between glass panes. Thanks to superior strength, clarity, and safety characteristics, SGP films are gaining traction in applications from architecture to automotive safety. forecasts the global SGP Interlayer Films Market to grow at a 6 % CAGR between 2025 and 2031.

This blog examines how market participants are strategizing for growth, whom the major players are, and which market segments are poised for expansion.

Market Overview & Key Segments

Application Segmentation

According to The Insight Partners, the SGP interlayer films market can be broadly segmented by application into:

- Automotive

- Building & Construction (Architectural / Glazing)

- Marine / Other sectors

In practice, the automotive segment often leads due to rigorous safety requirements and demand for laminated windshields and panoramic glass systems. Indeed, The Insight Partners report notes that the automotive application accounted for the largest share in 2023.

The architectural / building & construction segment is also a major driver, particularly in high-rise facades, curtain walls, skylights, and glazed partitions. The growing demand for energy efficiency, acoustic control, and greater occupant safety supports adoption of laminated glass systems using SGP interlayers.

Some newer or emerging sub‑applications include solar / photovoltaic glazing, security / bulletproof glass, and transportation (rail, marine, aviation), where SGP’s strength advantages are compelling.

Regional / Geographic Segmentation

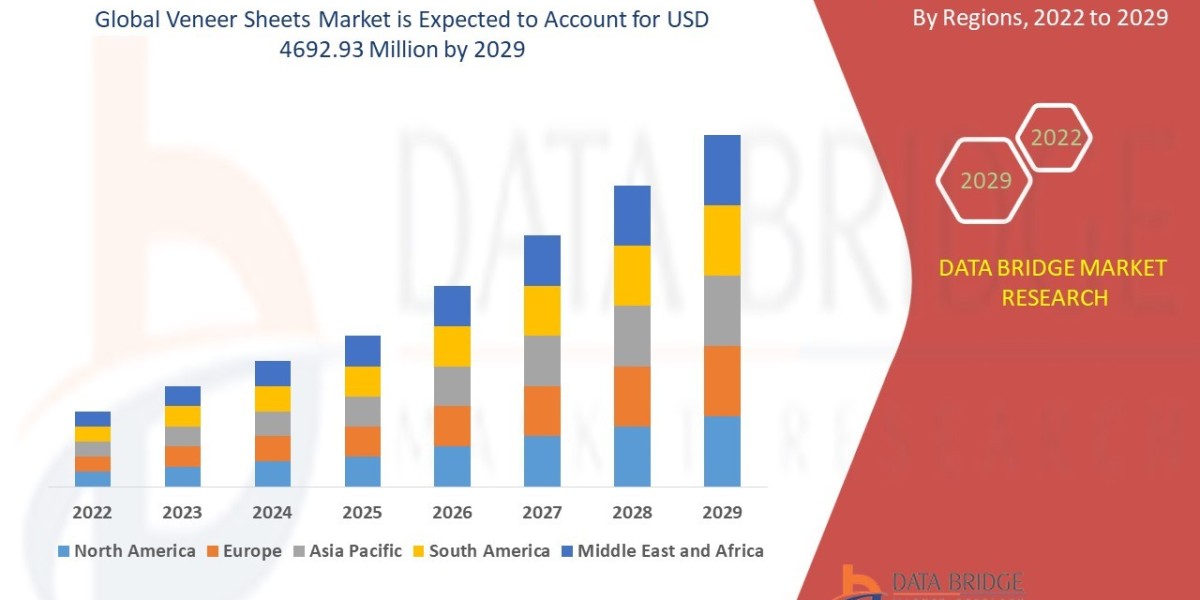

divides region coverage into North America, Europe, Asia Pacific, Middle East & Africa, and South & Central America.

Key regional observations:

- North America is expected to show one of the highest CAGRs, fueled by a mature automotive industry and robust architectural projects.

- Asia Pacific (notably China, India, Japan) is a fast-growing region, benefiting from urbanization, real estate development, and expanding vehicle markets.

- Europe remains important due to stringent safety and sustainability standards in buildings and transport.

- Middle East & Africa / Latin America present growth potential with rising infrastructure investment, though slower uptake than more mature regions.

Growth Drivers & Trends

Demand for Safety, Durability & Performance

- Stringent safety regulations in automobiles and buildings push manufacturers to adopt higher-performance interlayers like SGP, which resist impact, prevent shattering, and maintain integrity under stress.

- Rising adoption of laminated glass in façades, skylights, and bullet‑resistant applications increases demand for more advanced interlayers.

- Acoustic, UV, and energy control benefits of SGP interlayer systems are increasingly valued in premium architecture, especially in high-end office towers, museums, airports, etc.

Technological Innovation & Integration

- Integration with smart glass technologies (thermochromic, electrochromic) is seen as a future trend: the ability to dynamically control light or temperature using SGP‑laminated systems is attractive.

- Advances in automation, AI, and digital process control are streamlining production, improving yield, and reducing defects in interlayer film manufacture.

- R&D into eco‑friendly, recyclable, or bio‑based interlayer materials is gaining traction to meet regulatory and sustainability pressures.

Expansion Into New Applications

- Solar / photovoltaic glazing is an emerging opportunity: laminated glass modules with SGP interlayers can offer enhanced structural integrity and durability under environmental stress.

- Transportation beyond cars: aviation windows, train façades, bus windshields, marine glazing are potential growth frontiers given demands for safety and weight reduction.

- Security & bulletproof glass in high‑risk zones (government buildings, banks, embassies) is promising because SGP films boost resistance to penetration and shattering.

Strategic Growth Approaches Adopted by Players

Market participants in the SGP interlayer films space are deploying several strategic tactics to capture growth and maintain competitiveness:

- Capacity Expansion & Facility Build‑Outs

Many firms are investing to expand existing capacity or build new manufacturing facilities close to high-demand markets. This reduces logistics costs, shortens lead times, and mitigates import barriers.

- Strategic Partnerships & Vertical Integration

Collaborations with glass manufacturers, laminators, or architectural firms help secure downstream demand. Vertical integration helps players control raw materials, optimize upstream-to-downstream flow, and lock in supply agreements. Some players also form joint ventures in emerging markets.

- Mergers, Acquisitions & Consolidation

Acquisitions of niche laminators or technology firms enable incumbents to access novel processes, regional presence, or patented know-how. This bolsters the overall product portfolio and market reach.

- R&D, Product Differentiation & Innovation

Heavy focus on developing higher-transparency interlayers, better adhesion, durability under thermal or moisture stress, and integration with smart or energy-adaptive systems. Patents and proprietary technologies act as differentiators.

- Sustainability & Green Initiatives

Given growing regulatory and consumer pressure, companies are investing in recyclable materials, closed-loop recovery of waste interlayers, and reducing carbon footprint in manufacturing.

- Localization & Market Penetration in Emerging Regions

To overcome trade barriers or tariffs, global players often set up local production or partner with domestic firms in high-growth markets such as China, India, Southeast Asia, and Latin America.

Leading Players in the SGP Interlayer Films Market

According to The Insight Partners, key market players include:

- Dongguan Qun’an Plastic Industrial

- DuPont

- Eastman Chemical Company

- Genau Manufacturing Company LLP

- Huakai Plastic

- Jiaxing Willing Lamiglass Material GmbH

- KB PVB

- Kuraray

- PCII

- Shenbo Glass

Each company differentiates with specific strengths:

- DuPont leverages its strong brand and focus on sustainability, leveraging its chemistry and materials heritage.

- Eastman is notable for its R&D investment and active development of specialized interlayers for architectural, safety, and laminated glass markets.

- Kuraray often pursues vertical integration, controlling precursor supply (e.g. PVB resins) to optimize cost and quality.

- Sekisui, Everlam, Teijin tend to focus on specialty variants, regional strengths, or niche applications (e.g. acoustic, electrical, solar) to compete.

- Chinese players (e.g. Huakai, and other emerging entrants) often compete on price and scale, leveraging lower labor costs, local supply chains, and government support to break into markets.

Challenges, Risks & Constraints

While prospects look favorable, the SGP interlayer films market faces multiple headwinds:

- Volatility in raw material / petrochemical inputs can squeeze margins.

- High capital intensity and scale requirements make entry difficult for new players.

- Technological barriers: achieving desired mechanical, optical, and adhesive properties under varied climates is nontrivial.

- Regulation & standard certifications: meeting safety, building codes, and environmental standards in different regions is complex.

- Competition from lower-cost interlayers (e.g. standard PVB, EVA) or alternative materials may restrain adoption in price-sensitive markets.

Outlook & Strategy Recommendations

Given the projected 6 % CAGR (2025–2031) from , the SGP interlayer films segment looks set for steady growth . To capitalize:

- Target high-end / premium projects in architecture and automotive, where performance justifies premium pricing.

- Collaborate with glass manufacturers, architects, automakers early to specify SGP-based solutions and increase adoption.

- Focus R&D on differentiation (transparency, smart function, durability under climate extremes) to maintain competitive edge.

- Localize manufacturing in high-growth markets to minimize tariffs and logistics barriers.

- Embrace sustainability—develop recyclable or bio-based variants and highlight them in green building certification contexts (e.g. LEED).

- Strategic M&A or alliances can fill capability gaps, especially in downstream lamination, regional networks, or patent portfolios.

Get Sample PDF- https://www.theinsightpartners.com/sample/TIPRE00021632/

Conclusion:

The SGP interlayer films market is steadily evolving as a cornerstone of modern safety and performance standards in glass applications. With strong demand from both the construction and automotive sectors, backed by rising safety regulations and a global shift toward sustainable, durable materials, the market is set for consistent growth.

As innovation continues—through smart glass integration, new material formulations, and region-specific expansion—key players will need to align their strategies with changing consumer expectations and regulatory requirements. Those who invest in R&D, sustainability, and regional diversification will be best placed to capitalize on the market’s full potential in the years ahead.