Rigid plastic packaging plays a crucial role in packaging solutions due to its durability, ability to retain shape, and widespread applications across industries. The global market for rigid plastic packaging is expanding robustly, driven by rising consumer goods demand, advancements in packaging technology, and growing applications in e-commerce and food & beverage sectors. This article explores the current market landscape, key growth drivers, challenges, and regional dynamics shaping the industry.

Current Market Size and Forecast

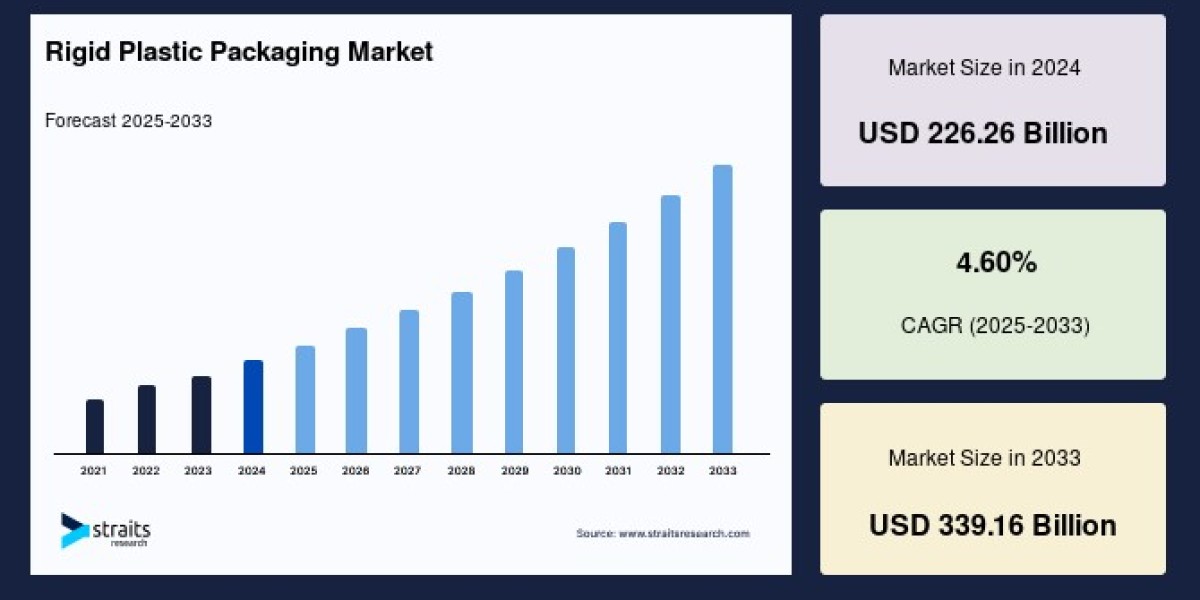

The global Rigid Plastic Packaging Market size was valued at USD 226.26 billion in 2024 and is projected to reach from USD 236.67 billion in 2025 to USD 339.16 billion by 2033, growing at a CAGR of 4.60% during the forecast period (2025-2033).

Understanding Rigid Plastic Packaging

Rigid plastic packaging refers to containers and packaging products made primarily from plastic resins that have a fixed, inflexible form. These include boxes, trays, bottles, jars, tubs, and cases that retain their shape whether empty or filled. Compared to flexible packaging, rigid plastics provide superior impact resistance, stiffness, and protection for products requiring stable packaging. They are widely used in food & beverage, household, healthcare, cosmetics, and industrial sectors, where packaging durability and product safety are paramount.

Key Market Drivers

Several factors are driving the growth of the rigid plastic packaging market:

Consumer Goods Demand: Rapid expansion in the consumer-packaged goods sector, especially in emerging economies, is fueling packaging demand. Increasing disposable incomes and urbanization contribute to higher consumption of packaged foods, beverages, cosmetics, and household products.

Packaging Advantages: Rigid plastic packaging offers unique benefits such as enhanced protection, longer shelf life, impact strength, and improved product visibility. These advantages help manufacturers differentiate their products on crowded retail shelves.

E-commerce Growth: The expanding global e-commerce sector boosts the need for durable packaging that can withstand complex supply chains and transportation logistics. Rigid packaging provides the strength and protection required for shipping fragile and high-value items.

Recycling and Sustainability Efforts: Increased awareness of environmental impacts has led to higher recycling rates for rigid plastics, encouraging adoption. Materials like PET and HDPE are commonly recycled, which helps reduce raw material use and pollution, aligning with sustainability goals.

Challenges and Market Restraints

Despite strong growth, the rigid plastic packaging market faces several challenges:

Environmental Concerns: The widespread use of plastic packaging contributes to pollution and ecosystem damage. Regulatory restrictions on plastic use and bans on single-use plastics in several regions limit market expansion.

Competition from Flexible Packaging: Flexible packaging offers advantages such as lower cost, lighter weight, and portability, making it attractive for certain applications. This rising preference poses competition to rigid packaging growth in some sectors.

Raw Material Price Volatility: Fluctuations in the cost of petrochemical-based raw materials affect manufacturing costs and product pricing, creating uncertainties for producers.

Material and Production Insights

Among polymers used in rigid packaging, polyethylene terephthalate (PET) holds the highest market share due to its recyclability, strength, and versatility in applications like food containers, aerosol cans, and drums. Polypropylene (PP) follows as a favored material for products demanding stiffness and high impact resistance.

Injection molding is the dominant production process, widely used in manufacturing containers and components for food & beverage packaging. Extrusion also plays a significant role, supplying plastic products for automotive, medical, packaging, and industrial use.

Regional Market Outlook

Asia-Pacific commands the largest market share and is the fastest-growing region with a CAGR of approximately 5.6%. Rapid urbanization, rising consumer disposable income, and increasing demand for packaged food, cosmetics, and beverages are primary growth drivers in countries like China, India, Vietnam, and Indonesia. The region’s booming e-commerce market further accelerates packaging demand.

Europe holds considerable market value, expected to grow at around 4.2% CAGR. The region emphasizes strict regulations on plastic use and waste management, pushing packaging companies to innovate with recycled materials and lightweight plastics. North America follows closely with strong pharmaceutical and healthcare sector needs fueling packaging requirements.

Industry Trends and Future Prospects

The rigid plastic packaging industry is evolving with several notable trends:

Sustainability Focus: Companies are developing biodegradable and recycled rigid plastic packaging to reduce environmental footprints, responding to consumer and regulatory pressures.

Technological Innovation: Advances in production techniques and materials improve packaging performance, cost-efficiency, and customization possibilities.

Shift in Consumer Preferences: Convenience, product safety, and aesthetics remain key factors, prompting innovation in packaging designs and formats.

Market Fragmentation: While a few global leaders dominate, numerous regional players contribute to diverse packaging solutions catering to varying market needs.

Conclusion

Rigid plastic packaging remains a vital segment in the global packaging industry, driven by its durability, versatility, and broad application across consumer and industrial sectors. Although environmental concerns and competition from flexible packaging pose challenges, innovation and sustainability initiatives are shaping the market’s future. With strong growth projected in Asia-Pacific and significant advances in material recycling, rigid plastic packaging is positioned to maintain its crucial role in protecting and enhancing products worldwide through 2033 and beyond.