The aerospace sector is experiencing a groundbreaking transformation propelled by artificial intelligence (AI), ushering in smarter design processes, enhanced safety, and streamlined operations from manufacturing to post-sale services. With rising demand for efficient, sustainable, and reliable aircraft combined with challenges such as complex supply chains and skill shortages, AI has rapidly emerged as a vital enabler for innovation and competitiveness in aerospace globally.

According to Straits Research, the global aerospace artificial intelligence size was valued at USD 1.36 billion in 2024 and is expected to grow from USD 1.95 billion in 2025 to reach USD 34.14 billion by 2033, growing at a CAGR of 43% during the forecast period (2025-2033). This explosive expansion underscores AI’s central role in reshaping engineering workflows, manufacturing efficiencies, and operational intelligence across multiple aerospace domains.

AI-Driven Breakthroughs Reshaping Aerospace

Generative AI for Design and Engineering Optimization

Generative AI algorithms are revolutionizing aircraft design by rapidly exploring design spaces and generating innovative configurations beyond human intuition. Aerospace giants like Airbus have successfully applied AI to create lightweight components and optimize aerodynamics, achieving significant fuel savings and performance improvements. Advanced 3D modeling and digital twin technologies enabled by AI allow engineers to simulate complex fluid dynamics and structural behavior faster and more accurately than traditional methods.

AI-Powered Manufacturing and Quality Control

AI integration in manufacturing lines transforms production efficiency and precision. Automated inspection systems using computer vision detect defects and deviations in real time, ensuring consistent high quality of critical parts. AI-driven robotics and factory automation reduce labor intensity and minimize errors, crucial in high-stakes environments where component failure is unacceptable.

Enhanced Supply Chain Resilience and Logistics

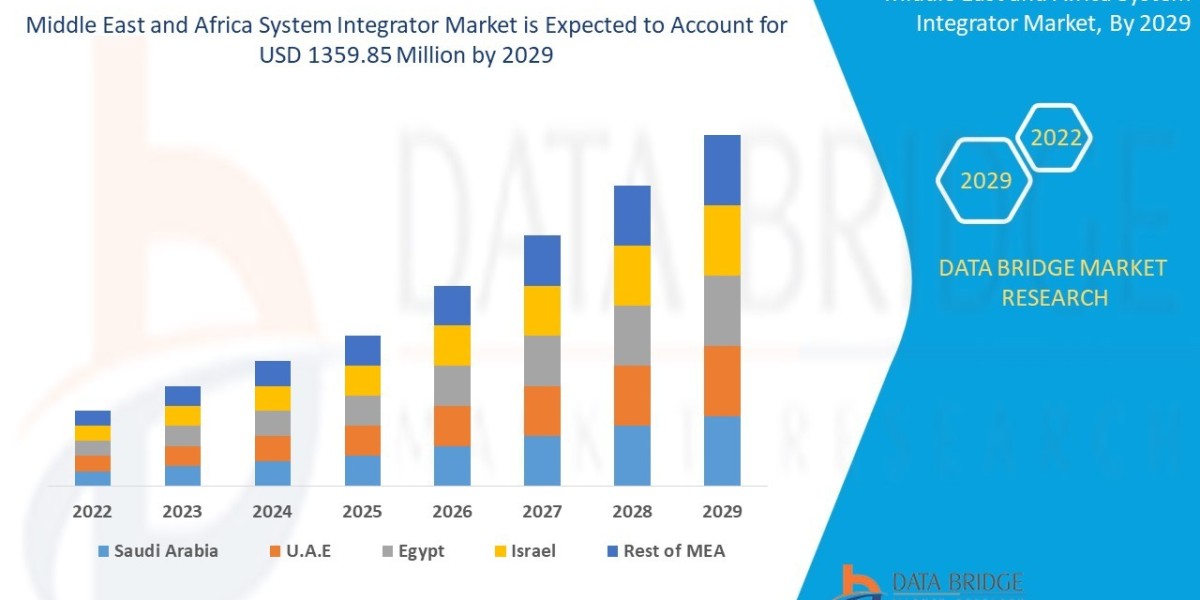

AI-driven predictive analytics help aerospace companies manage the notoriously complex supply chains by forecasting parts demand, optimizing inventory, and identifying bottlenecks before they impact production timelines. Real-time data integration across suppliers enables swift reaction to disruptions, reducing delays and costs.

Autonomous Systems and Flight Operation Optimization

AI plays an increasing role in autonomous and semi-autonomous flight control, enhancing pilot assistance systems with predictive situational awareness and decision support. AI algorithms optimize flight routes and fuel consumption dynamically based on weather and traffic data, promoting safer and more efficient operations.

Predictive Maintenance and Aftermarket Analytics

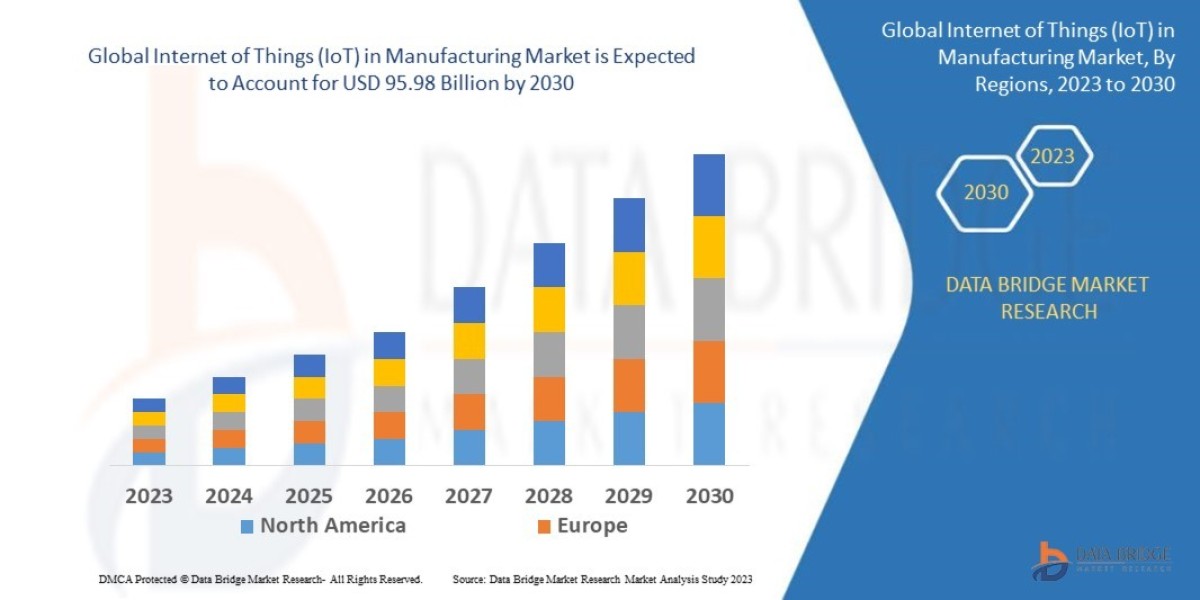

AI-powered IoT sensors embedded in aircraft continuously monitor system health, predicting failures before they occur and enabling proactive maintenance scheduling. This reduces unscheduled downtime and maintenance costs, contributing to both safety and profitability.

Leading Industry Players and Regional Developments

Airbus (France): A pioneer in integrating generative AI for aircraft and component design, advancing digital twin applications, and implementing AI-driven manufacturing automation.

Boeing (USA): Focuses on AI-enhanced supply chain optimization, autonomous flight research, and predictive maintenance systems.

GE Aviation (USA): Collaborates with Autodesk to deploy AI-driven turbine component redesign, achieving substantial weight reductions and efficiency gains.

Lockheed Martin (USA): Incorporates AI in systems engineering and defense aerospace programs, pioneering autonomous air traffic management and AI-enabled cockpit technologies.

Honeywell Aerospace (USA): Develops AI applications for avionics and flight management systems, emphasizing safety and adaptive control.

Rolls-Royce (UK): Leading in AI-driven engine diagnostics and remote monitoring platforms, extending propulsion system service life.

Mitsubishi Aircraft Corporation (Japan): Adopts AI-powered design simulation and quality control processes in regional aircraft manufacturing.

Safran Group (France): Innovates AI for additive manufacturing and predictive analytics in aerospace propulsion systems.

North America and Europe dominate AI adoption due to mature aerospace sectors, regulatory support, and substantial R&D investment. Asia-Pacific, led by China, Japan, and South Korea, shows rapid AI integration in manufacturing and emerging autonomous flight research funded by governmental initiatives.

Recent News Highlights

Airbus announced in early 2025 a breakthrough generative AI design project reducing cabin partition weight by 45%, improving fuel efficiency significantly.

GE Aviation and Autodesk collaborated to apply AI in turbine frame redesigns, consolidating parts and enhancing aerodynamic performances in mid-2025 deployments.

Boeing accelerated the adoption of AI for aircraft systems testing, shortening validation cycles by over 30% in 2025, reducing time to market.

Lockheed Martin unveiled its AI-enabled autonomous air traffic control system prototype in late 2024, projecting safer, scalable airspace management.

Honeywell Aerospace expanded its AI-driven adaptive autopilot features in commercial avionics systems, enhancing pilot situational awareness and flight safety in 2025.

Rolls-Royce launched AI-powered propulsion monitoring solutions providing predictive analytics for engine health in commercial airlines, demonstrated through pilot programs in 2025.

Growth Drivers and Future Outlook

The aerospace AI boom is galvanized by stringent fuel efficiency regulations, rising demand for autonomous and remotely-operated systems, and the need for enhanced safety and operational reliability. AI advances reduce design iteration times, cut costs, optimize manufacturing, and enable predictive systems that increase aircraft availability.

Future trajectories point to deeper AI-human collaboration, with generative AI tools augmenting engineer creativity while automation takes on repetitive tasks. Digital twins will become central to continuous aircraft monitoring and adaptive maintenance. Additionally, AI-based autonomous flight management and urban air mobility are poised for rapid growth, supported by government and industry alliances.

Challenges such as data security, model transparency, regulatory acceptance, and skills shortages require sustained attention to ensure safe and ethical AI integration. However, the aerospace sector’s commitment to innovation and safety is accelerating public and private efforts to overcome these obstacles.