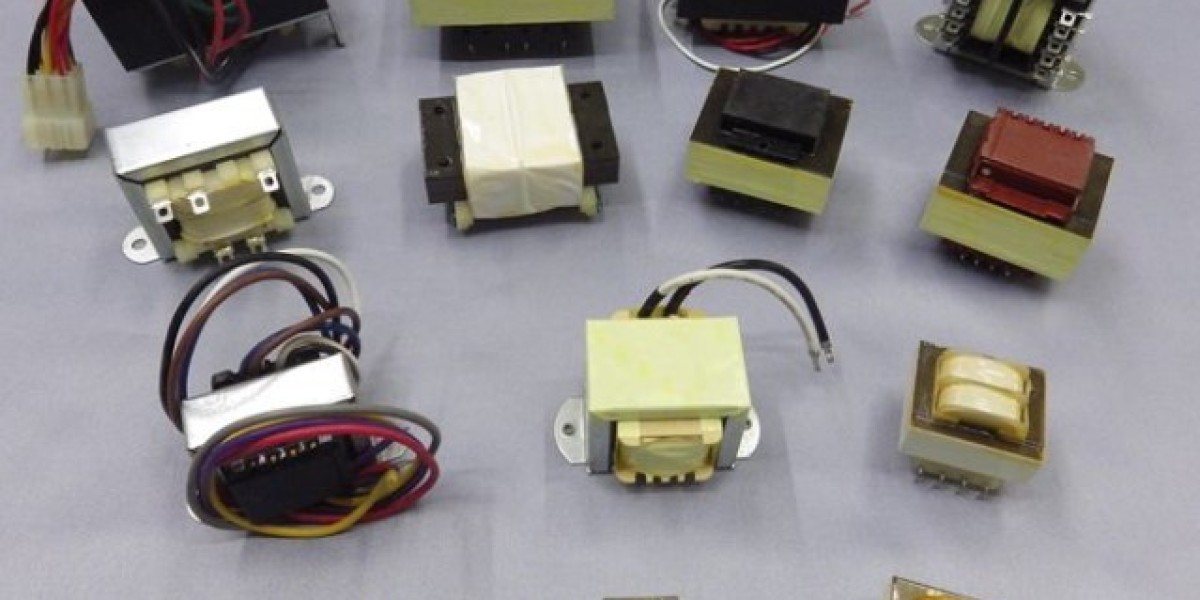

At the heart of electrical component production, a Low-frequency Transformer Factory represents a cornerstone in ensuring that stable and adaptable solutions are available for industries that rely on precise voltage regulation and consistent current distribution. Unlike high-frequency designs that prioritize compactness and fast switching, low-frequency units are frequently chosen for environments where durability, insulation, and longevity are critical factors.

When we discuss the significance of such manufacturing facilities, we see that their role extends beyond simply producing hardware. These factories must integrate technical expertise, standardized processes, and rigorous testing to achieve consistent outcomes. Every stage, from raw material selection to coil winding and lamination, contributes to creating devices that can manage power efficiently while maintaining safety.

The use of low-frequency transformers is vast, touching areas such as household systems, industrial controls, lighting solutions, and even specialized equipment that demands reliable performance over long operational periods. Their appeal often lies in their ability to handle fluctuations without compromising function, which makes them a preferred choice for many long-term installations.

Additionally, a factory dedicated to this category often invests in advanced equipment for winding accuracy, insulation reliability, and magnetic core preparation. These details may not be immediately visible to the end user, but they define how the transformer will behave under varying load conditions. By combining robust engineering with practical applications, these facilities ensure their products can be trusted in diverse scenarios.

Sustainability has also become a growing theme in the production of low-frequency transformers. Factories are exploring methods to optimize energy efficiency, minimize waste during production, and select eco-friendly materials where possible. This not only meets modern environmental expectations but also helps companies align with global standards.

When considering procurement, it is not only about the transformer itself but also about the factory's overall capability. Clients often look for assurance that quality control systems are in place, certifications are maintained, and the facility adapts to evolving industry trends. That adaptability ensures that users can rely on continuous support and innovation.

In summary, such a factory is not just a place of assembly but rather a hub of knowledge and innovation where design meets functionality. It demonstrates how precision manufacturing can intersect with everyday utility, creating products that remain dependable across different applications. For businesses and end users alike, this reliability translates into fewer interruptions, smoother operations, and better planning capacity.

For more details about related products, visit https://www.nbcbdz.com/product/